![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

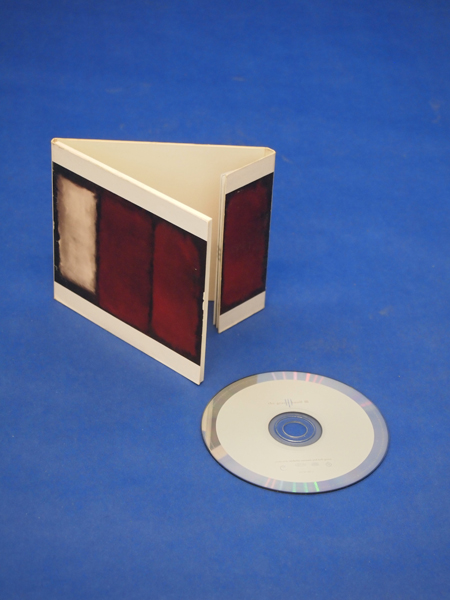

| Compact Disc: | |||

Narrative: Copper sourced from Chile, Peru, or Ecuador and produced in a factory in the United States; aluminum from Russia or China; polycarbonate plastic from California, South Africa, Somalia, South Korea, or Germany; boxite from Australia, and parts assembled in a factory in the United States. The larger supply chain includes: Petroleum refineries; Power generation and supply; Plastics material and resin manufacturing; Coal mining; Alumina refining and primary aluminum production; Oil and Gas extraction; Motor vehicle parts and manufacturing; Truck transportation; Iron and steel mills. This CD was given to me in Boston, Massachusetts and moved it to Portland, Oregon, and to New York City. It was stored in an attic in Somers, Connecticut for three years. I'm currently living with it in Brooklyn. The thick paper stock was made from pulp obtained by chemical means, known

as kraft pulping. Chips of wood were placed in a large, sealed container known

as a digester. The digester contained a strongly alkaline solution of sodium

hydroxide and sodium sulfide. Bleaching removes lignin and involves mixing

the pulp with a series of oxidizing chemicals that react with the lignin. After

each mixture, the pulp was washed with an alkaline solution that removes the

treated lignin. Fillers were added to the pulp. (A typical filler is a clay

known as kaolin. Other chemicals often added to pulp include starches or gums.

Rosin and alum are often added as sizers, making the paper less absorbent.)

Pulp was added to water to form slurry in order to make paper with an even

density. The slurry was pumped onto a moving mesh screen made up of very fine

wires of metal or plastic. Water drained through the small openings in the

mesh, and formed a sheet of wet material from the slurry. The sheet was moved

on a series of belst made of felt containing wool, cotton, and synthetic fibers.

The dried sheets moved between rollers known as calendars to make it smooth.

|

|

||

![]()