![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

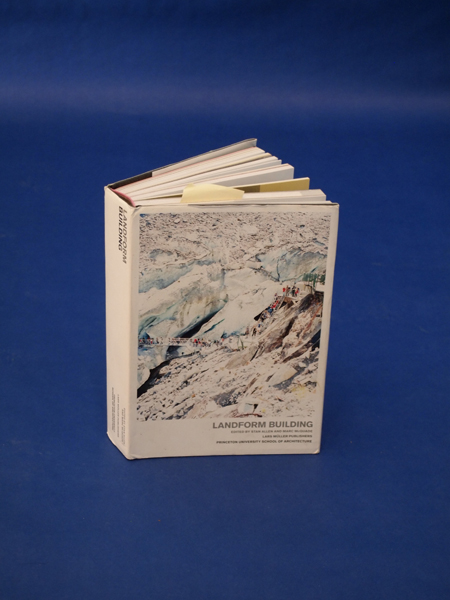

| Book: Landform Building | |||

Narrative: Landform Building. Edited by Stan Allen and Marc McQuade, Lars Muller Publishers, Printed and Binded by Regal Printing, Hong Kong Color printing inks are made primarily with linseed oil, soybean oil, or a heavy petroleum distillate as the solvent combined with organic pigments. The pigments are made up of salts of multiring nitrogen-containing compounds (dyes), such as yellow lake, peacock blue, phthalocyanine green, and diarylide orange. Inorganic pigments also are used in printing inks to a lesser extent. Some examples are chrome green (Cr2O3), Prussian blue (Fe4[Fe(CN)6]3), cadmium yellow (CdS), and molybdate orange (a mix of lead chromate, molybdate, and sulfate). Black ink is made using carbon black. White pigments, such as titanium dioxide, are used either by themselves or to adjust characteristics of color inks. Inks also contain additives such as waxes, lubricants, surfactants, and drying agents to aid printing and to impart any special characteristics. Printing ink is a $10 billion global industry. The paper was made from pulp obtained by chemical means, known as kraft pulping. Chips of wood were placed in a large, sealed container known as a digester. The digester contained a strongly alkaline solution of sodium hydroxide and sodium sulfide. Bleaching removes lignin and involves mixing the pulp with a series of oxidizing chemicals that react with the lignin. After each mixture, the pulp was washed with an alkaline solution that removes the treated lignin. Fillers were added to the pulp. (A typical filler is a clay known as kaolin. Other chemicals often added to pulp include starches or gums. Rosin and alum are often added as sizers, making the paper less absorbent.) Pulp was added to water to form slurry in order to make paper with an even density. After the typeset version of the book was reviewed and necessary changes made, it was printed and bound with the cover, resulting in a finished book. The typesetting and printing consists of filming and all subsequent steps are typically done by specialized vendors. Book binding also involves sewing the signatures together, gluing the spine, and inserting lining and trimming the edges. Finally the book is enclosed in a cover. I purchased this book on Amazon.com new for 40.95 with free 2-day shipping after it was recommended by Luke and Jessica at Thumb Projects. Green roofs, artificial mountains and geological forms; buildings you walk on or over; networks of ramps and warped surfaces; buildings that carve into the ground or landscapes lifted high into the air: all these are commonplace in architecture today. New technologies, new design techniques and a demand for enhanced environmental performance have provoked a re-thinking of architecture's traditional relationship to the ground. The book Landform Building sets out to examine the many manifestations of landscape and ecology in contemporary architectural practice: not as a cross-disciplinary phenomenon (architects working in the landscape) but as new design techniques, new formal strategies and technical problems within architecture. |

|

||

![]()