![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

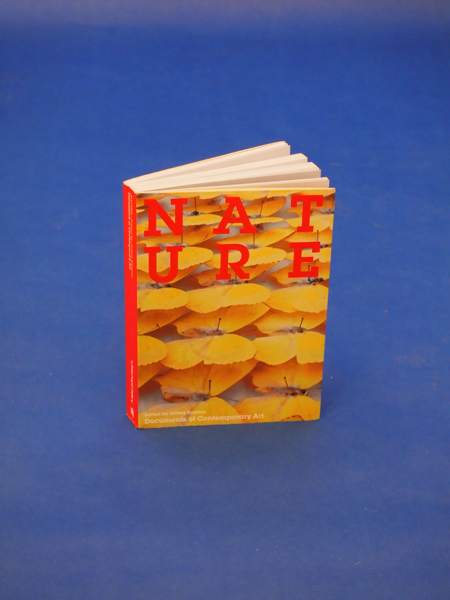

| Book: Nature - Documents of Contemporary Art | |||

Narrative: Nature; Edited by Jeffrey Kastner;

Documents of Contemporary Art Text for Nature was typeset and the mechanical copy of the manuscript was sent to a printer. The vendor then photographed the pages to produce page negatives. Next, negatives were stripped by hand onto large flat sheets known as 'goldenrods,' and the goldenrods were exposed with ultraviolet light. This resulted in 'blueprints," a positive reproduction of the book that is then checked for accuracy. The paper was made from pulp obtained by chemical means, known as kraft pulping. Chips of wood were placed in a large, sealed container known as a digester. The digester contained a strongly alkaline solution of sodium hydroxide and sodium sulfide. The mixture was heated to 320-356° F (160-180°C) at a pressure of about 116 pounds per square inch (800 kilopascals). Bleaching removes lignin and involves mixing the pulp with a series of oxidizing chemicals that react with the lignin. After each mixture, the pulp is washed with an alkaline solution that removes the treated lignin. Fillers are added to the pulp. A typical filler is a clay known as kaolin. Other chemicals often added to pulp include starches or gums. Rosin (a substance derived from pine trees) and alum (aluminum sulfate) are often added as sizers, making the paper less absorbent. Pulp is added to water to form slurry in order to make paper with an even density. The slurry is pumped onto a moving mesh screen made up of very fine wires of metal or plastic. Water drains through the small openings in the mesh, forming a sheet of wet material from the slurry. The sheet is moved on a belt made of felt containing wool and synthetic fibers, then on a belt made of felt containing cotton and other fibers. The dried sheet moves between rollers known as calendars to make it smooth. It is then wound on a large reel. After the typeset version of the book was reviewed and necessary changes made, it was printed and bound with the cover, resulting in a finished book. The typesetting and printing consists of filming and all subsequent steps are typically done by specialized vendors. Book binding also involves sewing the signatures together, gluing the spine, and inserting lining and trimming the edges. Finally the book is enclosed in a cover. An interview of mine was reprinted in this book and Whitechapel sent a copy to me. It moved with me from Manhattan to Brooklyn. |

|

||

![]()