![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

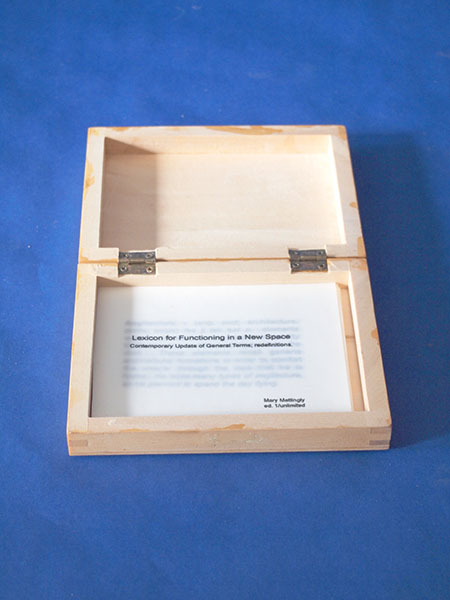

| Paper: Wood Box Encasing Lexicon for Functioning in a New Space | |||

Narrative: Wood Box Encasing Lexicon for Functioning in a New Space. The box was purchased from Marshalls Crafts and made in India. The most common softwood in the United States is Douglas fir. The acetate paper was acquired from Staples Office Supplies, made in India, and was printed on at Parsons School of Design on an Epson 1280 printer with Epson black ink. Acetate is derived from cellulose by deconstructing wood pulp with dissolving pulps into a purified fluffy white cellulose. The cellulose is then reacted with acetic acid and acetic anhydride with sulfuric acid. Then it is then put through partial hydrolysis to remove the sulfate and a sufficient number of acetate groups to give the product the desired properties. The most common form of cellulose acetate fiber has an acetate group on approximately two of every three hydroxyls. This is known as "acetate". After it is formed, cellulose acetate is dissolved in acetone into a viscous resin for extrusion through spinnerets. As the filaments emerge, the solvent is evaporated in warm air via dry spinning, producing fine cellulose acetate fibers.

|

|

||

![]()