![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

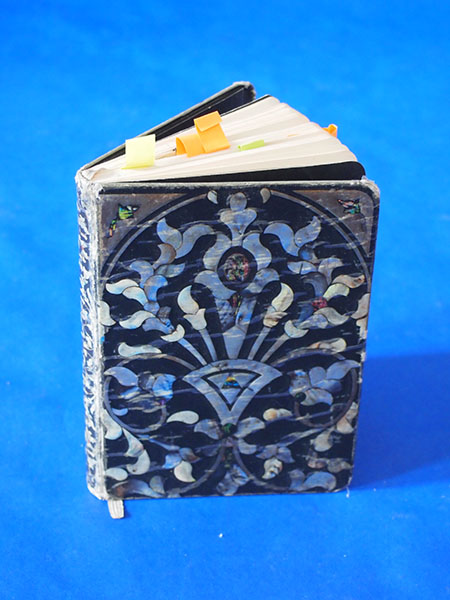

| Paper: Floral Journal | |||

Narrative: Floral journal by Paperblanks, intricate inlays photograph by Gerard de George ISBN 1-55156-383-5, 176 pages. The text paper is an archival quality sheet. Copyright 2003 Hartley & Marks Publishers, Inc. Made in China. Hartley&Marks Group was founded in 1973. Operating under the imprint of Cloudburst press, it began as a publisher of books dedicated to design, sustainable building, alternative health, and craft. In 1991, Hartley&Marks introduced Paperblanks, a collection of notebooks. Paper is acid free and derived from sustainable forest pulp, binder boards are made with 100% recycled materials. Paperblanks sources 100 percent of its pulpwood for its mills from plantation wood, with a threshold of up to 5 percent for legally sourced wood waste/residue. Paperblanks promotes their environmental and social commitments to specific groups listed on their website. The paper was made from pulp obtained by chemical means, known as kraft pulping. Chips of wood were placed in a large, sealed container known as a digester. The digester contained a strongly alkaline solution of sodium hydroxide and sodium sulfide. Bleaching removes lignin and involves mixing the pulp with a series of oxidizing chemicals that react with the lignin. After each mixture, the pulp was washed with an alkaline solution that removes the treated lignin. Fillers were added to the pulp. (A typical filler is a clay known as kaolin. Other chemicals often added to pulp include starches or gums. Rosin and alum are often added as sizers, making the paper less absorbent.) Pulp was added to water to form slurry in order to make paper with an even density. The slurry was pumped onto a moving mesh screen made up of very fine wires of metal or plastic. Water drained through the small openings in the mesh, and formed a sheet of wet material from the slurry. The sheet was moved on a series of belst made of felt containing wool, cotton, and synthetic fibers. The dried sheets moved between rollers known as calendars to make it smooth. I received this as a birthday gift from Allison Collins in 2002 and it sat on my bookshelf in Bed Stuy, Brooklyn. I used it to plan some details of artwork I was working on at the time, including the Waterpod project. The notebook moved with me to Eastern Parkway in Brooklyn, into storage at Moshie Self Storage, and out of storage after the Waterpod to Varick Street in Manhattan. It is currently with me in Greenpoint, Brooklyn. |

|

||

![]()