![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

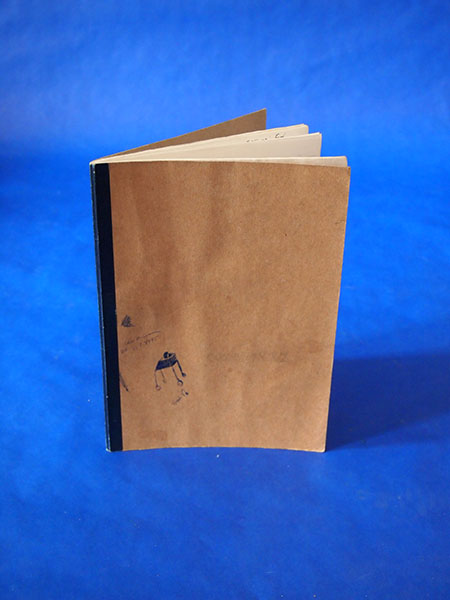

| Paper: Brown Journal 2 | |||

Narrative: Brown journal Lined Note, made from recycled paper Line interval: 6mm. B5 size: 6.9 x 9.8" I purchased these journals in bulk at Muji, SOHO NY in 2006 because they were 100% recycled and foldable. Bound with adhesive and twine made of cotton. Recycled paper pulp is made by mixing used paper with water. Rotating fins in the pulper reduce the paper to individual fibers, producing a paper slurry. That pulp is then washed and refined. At that stage, contaminants like small pieces of glass, staples, plastic, and any other non-fiber materials that were mixed in with paper are removed. About 2% of the recovered fiber is lost during the papermaking process and becomes compost, landfill cover, or feedstock for aerobic or anaerobic water treatment systems. Clean paper slurry is then moved through the paper machine on a series of screens. As the pulp travels, water drains away from the slurry. The remaining paper fibers are pressed with rollers and dried to form large sheets of paper. Computerized sensors are made in China monitor each stage of the process. As the paper exits the machine, it is either stacked in large sheets or wound into large rolls. The recycled paper is then sent to a converting facility where it is transformed into a box, core or tube, fiber can, folding carton, or other consumer or industrial product.

|

|

||

![]()