![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

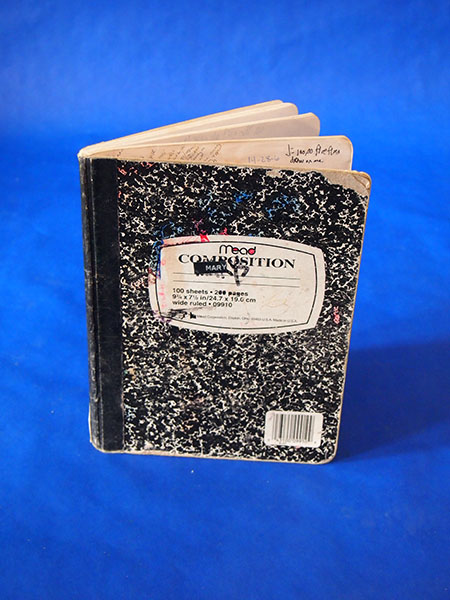

| Paper: Composition Notebook 1 | |||

Narrative: Composition Notebook; Thread stitch binding, 80-100 pages, hardcover 250g ivory board/ coated card/ brown paper. Manufactured in China by Shenzhen Gold Printing Culture Co., Ltd., Manufactured in China by Guangzhou Yifeng Paper Printing & Packing Co., Ltd Manufactured in Uttar Pradesh, India by R.K. International The paper was made from pulp obtained by chemical means, known as kraft pulping. Chips of wood were placed in a large, sealed container known as a digester. The digester contained a strongly alkaline solution of sodium hydroxide and sodium sulfide. Bleaching removes lignin and involves mixing the pulp with a series of oxidizing chemicals that react with the lignin. After each mixture, the pulp was washed with an alkaline solution that removes the treated lignin. Fillers were added to the pulp. (A typical filler is a clay known as kaolin. Other chemicals often added to pulp include starches or gums. Rosin and alum are often added as sizers, making the paper less absorbent.) Pulp was added to water to form slurry in order to make paper with an even density. The slurry was pumped onto a moving mesh screen made up of very fine wires of metal or plastic. Water drained through the mesh, and formed a sheet of wet material from the slurry. The sheet was moved on a series of belst made of felt containing wool, cotton, and synthetic fibers. The dried sheets moved between rollers known as calendars. The points of most ballpoint pens are made out of brass, which is an alloy of copper and zinc. Oleic acid, castor oil, or a sulfonamide plasticizer are also used. The markers bodies, caps, and plugs are formed from plastic resin. The marker reservoirs are formed from polyester. Powder and water are used to form the felt writing tip. In addition, markers require ink, and the pigments and synthetic substances used to make it. To make the body of the marker, plastic resin is injection-molded into a marker body. Injection molding involves heating plastic resin, into a molten state and forcing (injecting) it into a mold of the desired shape, then allowing it to cool and harden. Marker caps and plugs are formed in the same manner as the barrel. The nib, or tip, of the marker is made from powder mixed with water, molded, and baked into its pointed or flat form. Using one machine for all the following functions, an assembler then places a polyester cylinder inside the marker barrel to form a reservoir for the ink, fills the reservoir with ink, and inserts the nib at the bottom and the cap at the top. The markers are then placed into color assortment and packaged for retail marketing. This notebook was used in 2002 - 2003 in Brooklyn New York, and traveled with me from Brooklyn to Queens to the Waterpod to Manhattan to Brooklyn. |

|

||

![]()