![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

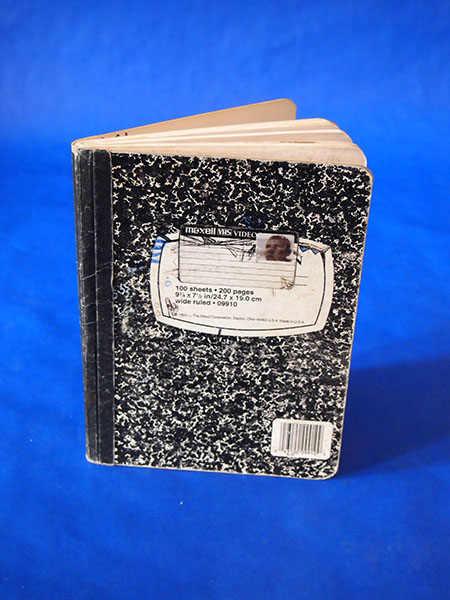

| Paper: Composition Notebook 2 | |||

Narrative: Composition Notebook; Thread stitch binding, 80-100 pages, hardcover 250g ivory board/ coated card/ brown paper Manufactured in China by Shenzhen Gold Printing Culture Co., Ltd., The paper was made from pulp obtained by chemical means, known as kraft pulping. Chips of wood were placed in a large, sealed container known as a digester. The digester contained a strongly alkaline solution of sodium hydroxide and sodium sulfide. Bleaching removes lignin and involves mixing the pulp with a series of oxidizing chemicals that react with the lignin. After each mixture, the pulp was washed with an alkaline solution that removes the treated lignin. Fillers were added to the pulp. (A typical filler is a clay known as kaolin. Other chemicals often added to pulp include starches or gums. Rosin and alum are often added as sizers, making the paper less absorbent.) Pulp was added to water to form slurry in order to make paper with an even density. The slurry was pumped onto a moving mesh screen made up of very fine wires of metal or plastic. Water drained through the small openings in the mesh, and formed a sheet of wet material from the slurry. The sheet was moved on a series of belst made of felt containing wool, cotton, and synthetic fibers. The dried sheets moved between rollers known as calendars to make it smooth. This notebook was used as a journal from 2001-2002 in Brookyn, NY. It was moved into storage on Staten Island 2006 and then to Manhattan in 2010. There is a sticker of friend Ramsay Barnes on the cover, that he made at MICA in Baltimore. There is a sticker underneath from Maxell VHS Videotape. R. Stanton Avery® manufactured self-adhesive labels with a paper surface with a coat of adhesive and then stick a liner onto the adhesive. This liner had a special silicone coating. Pressure sensitive labels use wax paper as a backing. Litho stock and latex are used as base materials.

|

|

||

![]()