![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

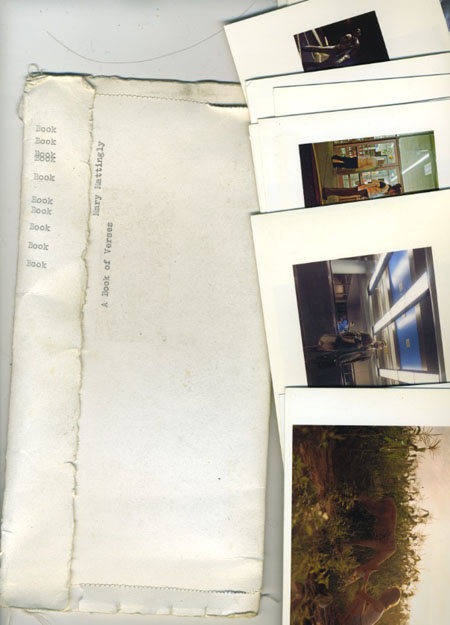

| Photos and Envelope | |||

Narrative: The thick paper stock was made from pulp obtained by chemical means, known as kraft pulping. Chips of wood were placed in a large, sealed container known as a digester. The digester contained a strongly alkaline solution of sodium hydroxide and sodium sulfide. Bleaching removes lignin and involves mixing the pulp with a series of oxidizing chemicals that react with the lignin. After each mixture, the pulp was washed with an alkaline solution that removes the treated lignin. Fillers were added to the pulp. (A typical filler is a clay known as kaolin. Other chemicals often added to pulp include starches or gums. Rosin and alum are often added as sizers, making the paper less absorbent.) Pulp was added to water to form slurry in order to make paper with an even density. The slurry was pumped onto a moving mesh screen made up of very fine wires of metal or plastic. Water drained through the small openings in the mesh, and formed a sheet of wet material from the slurry. The sheet was moved on a series of belst made of felt containing wool, cotton, and synthetic fibers. The dried sheets moved between rollers known as calendars to make it smooth. Typewriters use hundreds to thousands of moving parts. Carrying case is made of steel and plastic. Steel is the material used for most of the parts in standard models. The platen is a steel tube covered with a rubber sleeve. The rubber sleeves are made of a special form of rubber from the "buna-N" family. Glue is used to adhere the rubber sleeve to the platen tube. The keys are molded of plastic in a two-shot, injection-molding process that made white characters with the surrounding key tops in other colors. From the 1970s forward, a pad printing process has been used to apply the characters in ink and coat the keys with a clearcoat finish. Mylar ribbons with ink on one side are used to transfer the typeface. These ribbons are contained in plastic cartridges that could be thrown away. Miscellaneous materials are also used. These include glue, paint, chemical solvents and other fluids, zinc and chromium for plating some components, and acetic acid for building protective coatings on some parts. Cotton thread was purchased at Joanne Fabrics and sewn on a Singer machine that was my mother's.

|

|

||

| r |

![]()