![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

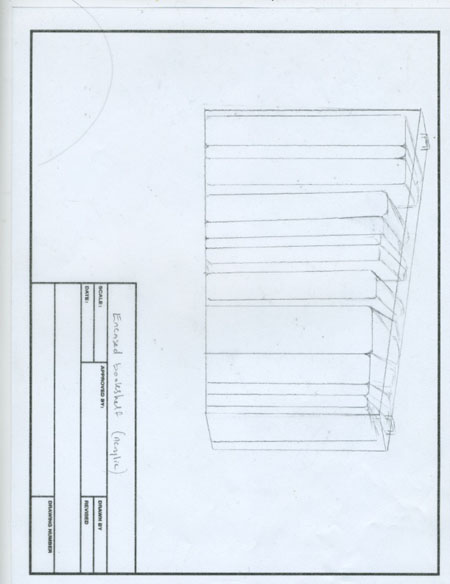

| Drawing of Enclosed Bookshelf | |||

Narrative: Acetate is derived from cellulose by deconstructing wood pulp with dissolving pulps into a purified fluffy white cellulose. The cellulose is then reacted with acetic acid and acetic anhydride with sulfuric acid. Then it is then put through partial hydrolysis to remove the sulfate and a sufficient number of acetate groups to give the product the desired properties. The most common form of cellulose acetate fiber has an acetate group on approximately two of every three hydroxyls. This is known as "acetate". After it is formed, cellulose acetate is dissolved in acetone into a viscous resin for extrusion through spinnerets. As the filaments emerge, the solvent is evaporated in warm air via dry spinning, producing fine cellulose acetate fibers. The points of most ballpoint pens are made out of brass, which is an alloy of copper and zinc. Oleic acid, castor oil, or a sulfonamide plasticizer are also used. The markers bodies, caps, and plugs are formed from plastic resin. The marker reservoirs are formed from polyester. Powder and water are used to form the felt writing tip. In addition, markers require ink, and the pigments and synthetic substances used to make it. To make the body of the marker, plastic resin is injection-molded into a marker body. Injection molding involves heating plastic resin, into a molten state and forcing (injecting) it into a mold of the desired shape, then allowing it to cool and harden. Marker caps and plugs are formed in the same manner as the barrel. The nib, or tip, of the marker is made from powder mixed with water, molded, and baked into its pointed or flat form. Using one machine for all the following functions, an assembler then places a polyester cylinder inside the marker barrel to form a reservoir for the ink, fills the reservoir with ink, and inserts the nib at the bottom and the cap at the top. The markers are then placed into color assortment and packaged for retail marketing.

|

|

||

![]()