![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

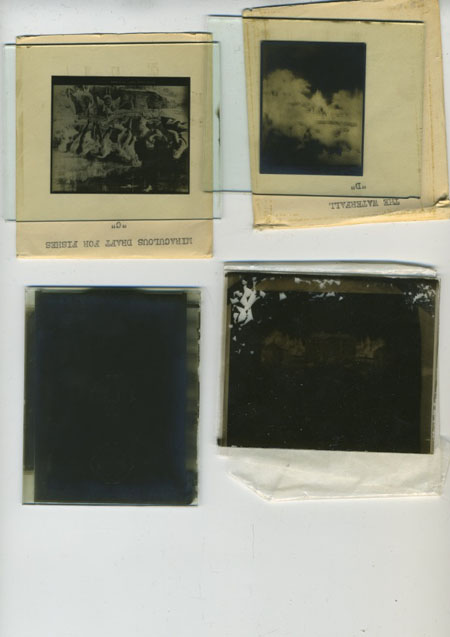

| Glass Negatives | |||

Narrative: These glass negatives were found. The collodion process is an early photographic process, invented by Frederick Scott Archer. It was introduced in the 1850s and by the end of that decade it had almost entirely replaced the first practical photographic process, the daguerreotype. During the 1880s the collodion process, in turn, was largely replaced by gelatin dry plates—glass plates with a photographic emulsion of silver halides suspended in gelatin. The dry gelatin emulsion was not only more convenient but could be made much more sensitive, greatly reducing exposure times. bromide and iodide salts dissolved in collodion, which is a solution of pyroxylin in alcohol and ether. This mixture poured onto a cleaned glass plate, and allowed to sit for a few seconds. The plate then placed into a solution of silver nitrate in water, which would convert the iodide, bromide salts to silver iodide, bromide, respectively. Once this reaction complete, the plate removed from the silver nitrate solution, and exposed in a camera while still wet. It developed with a solution of iron sulfate, acetic acid and alcohol in water. Then plate fixed with sodium thiosulfate. After that the plate washed with tap water. Finally it protected with gum sandarac varnish. Typewriters use hundreds to thousands of moving parts. Carrying case is made of steel and plastic. Steel is the material used for most of the parts in standard models. The platen is a steel tube covered with a rubber sleeve. The rubber sleeves are made of a special form of rubber from the "buna-N" family. Glue is used to adhere the rubber sleeve to the platen tube. The keys are molded of plastic in a two-shot, injection-molding process that made white characters with the surrounding key tops in other colors. From the 1970s forward, a pad printing process has been used to apply the characters in ink and coat the keys with a clearcoat finish. Mylar ribbons with ink on one side are used to transfer the typeface. These ribbons are contained in plastic cartridges that could be thrown away. Miscellaneous materials are also used. These include glue, paint, chemical solvents and other fluids, zinc and chromium for plating some components, and acetic acid for building protective coatings on some parts.

|

|

||

![]()