![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

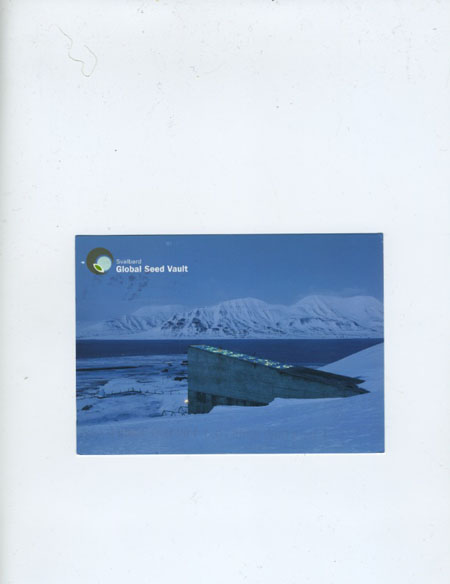

| Global Seed Vault Postcard | |||

Narrative: A postcard from Jess Segall during her trip to Svalbard's Seed Bank, the Doomsday Seed Vault funded by Monstanto, Syngenta, and the Rockefellers. Digital C-prints are the result of printing a digital file on a continuous tone printer that uses silver-based paper. The photograph is created by exposing the paper with light sources (such as lasers or LEDs) and then processing the exposed paper with traditional chemistry. The most common papers are type-C papers processed in RA-4 chemistry. The continuous tone printers include the Lightjet, Durst Lambda, and the Chromira, and labs that make these types of prints will usually advertise that they use one of those three brands. The paper is made up of Silver halide, Resin, Baryta, Polyester, Linen, Polyethylene, Strontium, Amoniac, Silver nitrate (silver bullion or silver foil with nitric acid resulting in silver nitrate, water, and oxides of nitrogen), Gelatin from animal hooves, Sulfur, Alum, Formaldehyd (produced industrially by the catalytic oxidation of methanol), Glyoxal, Saponin (plant-derived from the maple tree, for example), Phenol (from petroleum), Thymol (organic from thyme oil), Antiseptics, Hardeners to improve the physical characteristics of the emulsion during storage and development, a wetting agent to reduce surface tension of the dried emulsion such as Saponin, Stabilizers to prevent development of unexposed grains when the image is developed, Gelatine hardener to prevent the gelatin to swell, Surfactants, lubricants and anti static agents to control the properties of the dried emulsion, color sensitizing dyes to expand the range of light sensitivity, the sensitivity of the emulsion. Chemical waste was sent to: Guiyu, China; India, New Delhi; Pakistan, Karachi; Bantam Island, Indonesia - e waste from Singapore and Malaysia; Indonesia; Nigeria, Lagos; Ghana, Accra; Ghana, Agbogbloshie - outside Accra; India, Bangalore. Layered paper is produced by putting a number of sheets of paper in a stack and gluing them together. Using a photographic process a negative of the image is exposed to a flat plate and coated with a light sensitive material. The plate is developed, and the image area is coated with an oily material that will attract ink but repel water. The non-image area is coated. One plate per color is created. The plate is passed under a roller on the printing press, which coats it with water. The image area on the plate, previously treated with the oily material, repels the water and remains uncoated. An ink roller is next passed over the plate. A rubber roller is then passed over the printing plate and the ink from the plate is transferred to it. The card paper is passed under the rubber roller and the ink is transferred to it. This is done in color order. The ink dries before it enters the next roller assembly. This process of wetting, inking, and printing is continuous throughout the card manufacturing run. After both sides of the pasteboards are printed, they are transported to a card cutting station. Precision-cutting machines cut the cards out from the printed sheets. |

|

||

![]()