![]() body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

body | color | collections | commodity | cube | document | fabric | fetish | gender | glass | home | identity | living | machine | metal | minimal | mobility | narrative | olfactory | organic |

![]() pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

pain | paper | plastic | plugs | power | protective | rectangular | ritual | round | sound | souvenir | spiritual | style | text-based | time | tool | touch | uniform | value | visual | warm | wood

| Postcard | |||

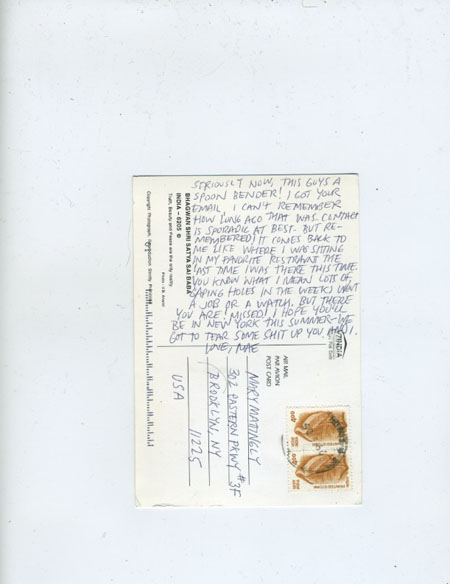

Narrative: Postcard from Mae Fatto in 2006 when she was traveling in India with Lucas and Bharat, ilustrating time and communication lost. A ballpoint pen on a glossy-face, matte-verso printed postcard with glue-based stamps and an ink-based stamp. The face of the postcard required editing softward and a camera. Printed text reads: Bhagwan Shri Satya Saibaba India - 6205 (Truth, Beauty, and Peace are the only reality) Copyright Photograph Reproduction Shirley Pribin. The paper was made from pulp obtained by chemical means, known as kraft pulping. Chips of wood were placed in a large, sealed container known as a digester. The digester contained a strongly alkaline solution of sodium hydroxide and sodium sulfide. The mixture was heated to 320-356° F (160-180°C) at a pressure of about 116 pounds per square inch (800 kilopascals). After each bleach mixture, the pulp is washed with an alkaline solution that removes the treated lignin. Fillers are added to the pulp. Other chemicals often added to pulp include starches or gums. Rosin (a substance derived from pine trees) and alum (aluminum sulfate) are often added as sizers, making the paper less absorbent. Pulp is added to water to form slurry . The slurry is pumped onto a moving mesh screen made up of very fine wires of metal or plastic. Water drains, forming a sheet of wet material. The sheet is moved on a series of belst made of felt containing wool, cotton, and synthetic fibers. The dried sheets move between rollers known as calendars to make it smooth. Layered paper is produced by putting a number of sheets of paper in a stack and gluing them together. The pen's body, caps, and plugs are formed from plastic resin. The marker reservoirs are formed from polyester. Powder and water are used to form the felt writing tip. In addition, felt-tipped pens require ink, and the pigments and synthetic substances used to make it. Toluol and xylol are synthetics used as solvents in dye as well as chemicals such as cyclic alkylene carbonates. Conventional additives, such as nonylphenylpolyglycol ether, alkylpoly-glycol ether, fatty acid polyglycol ester, or fatty alcohol ethoxalates, and preservatives, such as ortho-phenolphenyl and its sodium salt, ortho-hydroxydiphenyl, or 6-acetoxy-2,4-dimethhyl-m-dioxane, may also be added to the mixture. To make the body of the pen, plastic resin is injection-molded into a pen's body. The nib, or tip, of the marker is made from powder mixed with water, molded, and baked into its pointed or flat form. Using one machine for all the following functions, an assembler then places a polyester cylinder inside the marker barrel to form a reservoir for the ink, fills the reservoir with ink, and inserts the nib at the bottom and the cap at the top. |

|

||

![]()